Quality without compromise

The process of manufacturing welded products requires a professional approach from start to finish. A sophisticated quality policy extends to every single area of our production.

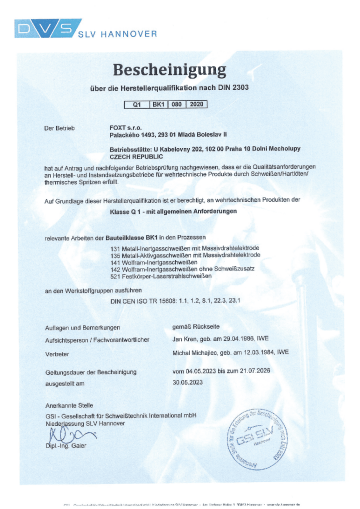

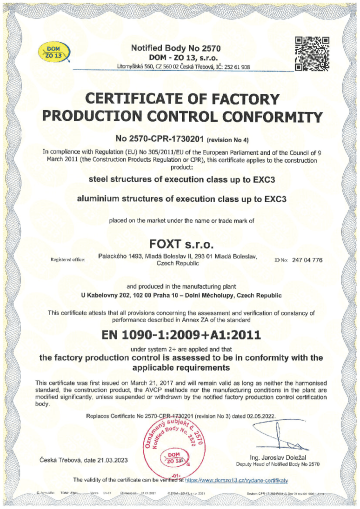

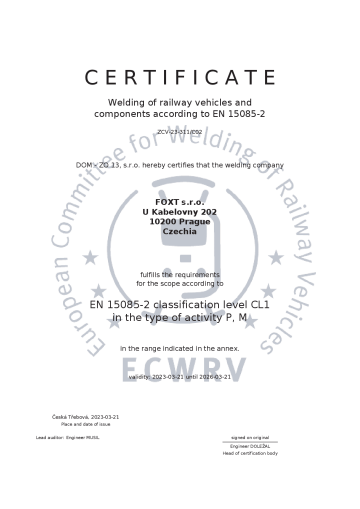

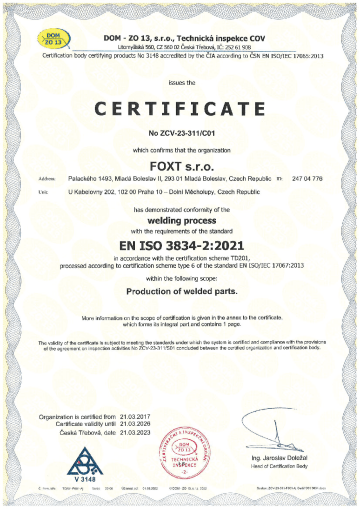

Certification

Quality is a concept that means a lot to us, which is why we focus on making sure that it is not just on paper, but also firmly rooted throughout the entire production process all the way to the final product

Welding is one of the critical technologies for us and we take the utmost care.